- Homepage

- ISO6022 - DIN 24333

DESIGN AND MANUFACTURING OF HYDRAULIC CYLINDERS AND LIFTING ACCESSORIES

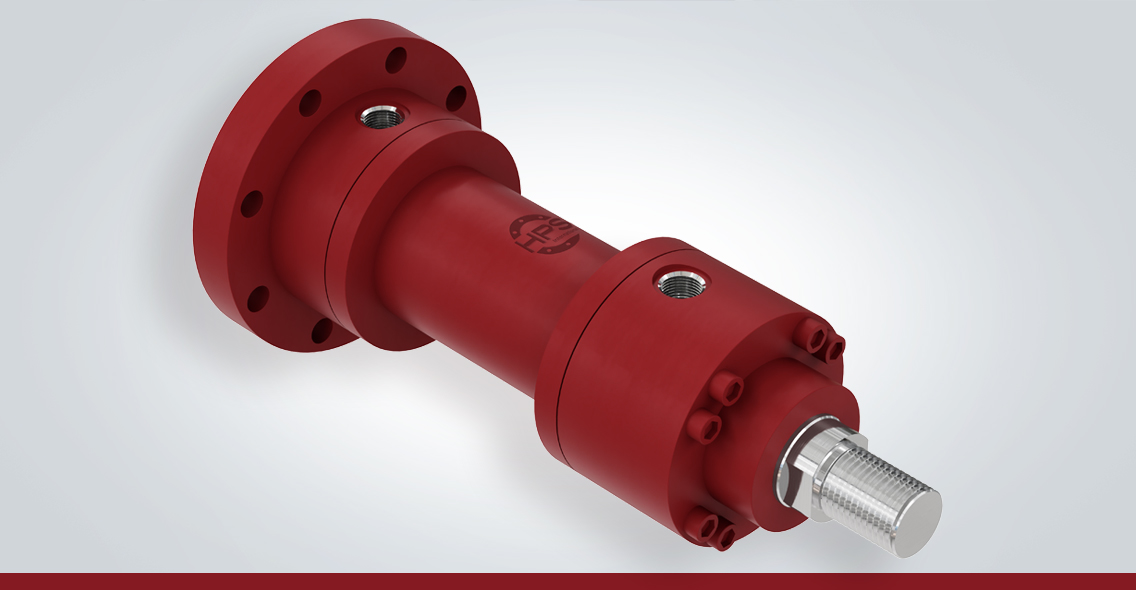

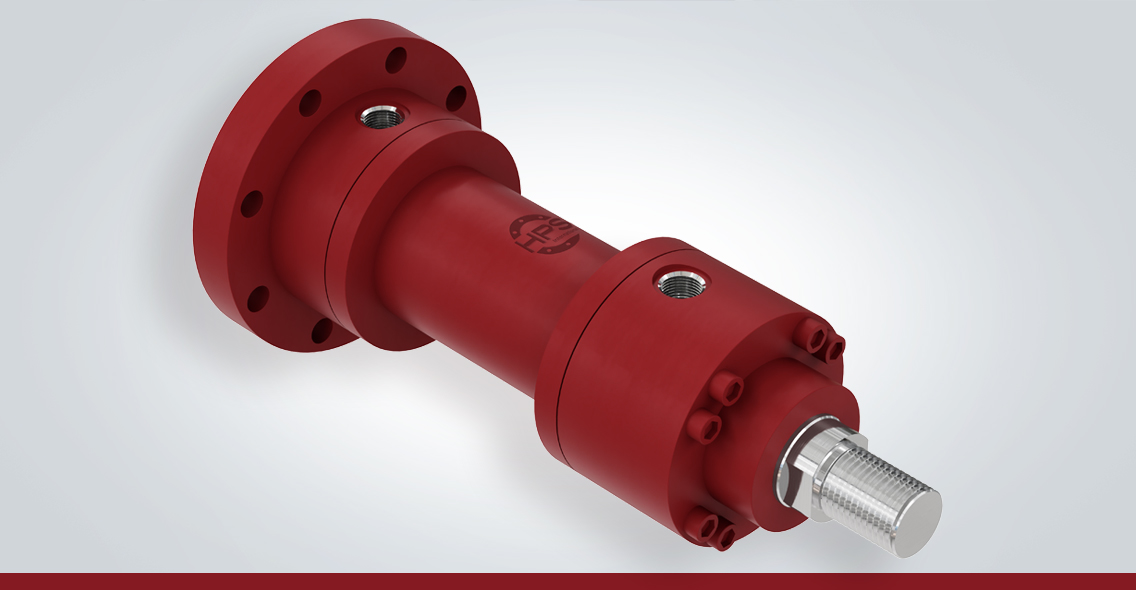

- ISO 6022 – DIN 24333 Hydraulic Cylinders

- Heavy-Duty Strength and Reliability for Demanding Applications

-

- Industrial systems operating under high pressure, heavy loads, and extreme conditions require hydraulic components that can deliver consistent performance over long service life. The ISO 6022 – DIN 24333 cylinder series (H250 Co) meets these demands, providing engineers with a standardized, robust solution suitable for new equipment or replacement projects.

-

- By adhering to international standards, these cylinders ensure interchangeability and simplified maintenance, while their modular design guarantees strength, durability, and reliable operation in challenging environments.

-

- Technical Highlights

- The H250 Co series offers:

- - Bores: Ø50 to 320 mm

- - Working pressure: 250 bar

- - Sensor options: inductive and linear

- - Operating temperature: –20 °C … +240 °C (with PTFE seals)

-

- The high-strength modular construction supports multiple mounting options and accessories, allowing precise adaptation to diverse industrial systems without compromising performance.

-

- Applications Across Heavy-Duty Industries

- ISO 6022 – DIN 24333 cylinders are designed for sectors such as:

- - Machine tools, presses, and forming equipment

- - Mining and steelworks

- - Construction and heavy engineering

- - Mold & die applications requiring high durability

-

- Wherever strength, reliability, and long service life are essential, these cylinders deliver proven performance.

-

- The HPS Experience

- Leveraging decades of expertise in hydraulic engineering, HPS International ensures that every ISO/DIN cylinder—including the H250 Co—is manufactured with precision, quality, and adaptability in mind. This experience guarantees safe, reliable, and efficient operation even in the most demanding industrial environments.